Welcome to part 3 of the model making of the “La Provencale”.

Even during this construction phase, some things didn’t go as planned.

Problems I had with model making the “La Provencale”

For example, it would have been advantageous to pre-soak both the railing and the support strips for the seat planks in water and gently bend them with a bent iron.

The railing would then likely have been easier to glue along its length.

The same applies to the support strips for the seat planks. The tension in the wood was so high that, despite clamping, they shifted during gluing and had to be adjusted afterward.

When bluing the brass fittings with Ammo’s “Photoetch Blurishing Fluid,” there were a few small areas that simply wouldn’t turn black.

This is either due to the metal alloy or to impurities on the metal. It might have been a good idea to clean the parts beforehand in isopropanol.

In addition, the black surface was slightly greasy and easy to remove. It’s possible the metal wasn’t sufficiently dry after the bluing process.

To shorten the brass and white metal parts, I used special pliers for cutting hard metals. With the small parts, such as the eye bolts, I had to be incredibly careful because they have a tendency to fly off and disappear forever.

The holes for the rudder pins were unfortunately a bit too small, so I could only insert the pins with the help of a hammer. I had previously selected a drill bit that matched the diameter of the brass profile.

The good things with model making the “La Provencale”

Although the bucket and blocks, for example, are made of plastic, they could be easily stained with wood stain.

A good tip I got in a video on “Mario’s Schiffsmodellbau” for tapering the mast and spars towards the tip is to divide them into equal 5 cm sections from top to bottom. Then, plane the first section all the way around with a very finely adjusted model plane. Next, plane the second and first sections, then the third section, again going over the second and first sections, and so on. The result is that the round timber tapers progressively towards the tip. Finish with sandpaper. This method eliminates the need for a lathe.

I documented the model making of the “La Provencale” part 3 also in a gallery and on video and show the work steps in detail.

Part 3 covers the following topics:

– Sanding mast base, keelhog and railing

– Rounding off the frame ends

– Staining the seat supports

– Painting the keelhog and railings

– Second coat of blue paint in railings

– Painting the mast base

– Second white coat of paint on the keelhog

– Applying the keelhog

– Applying the railing

– Attaching the mast base

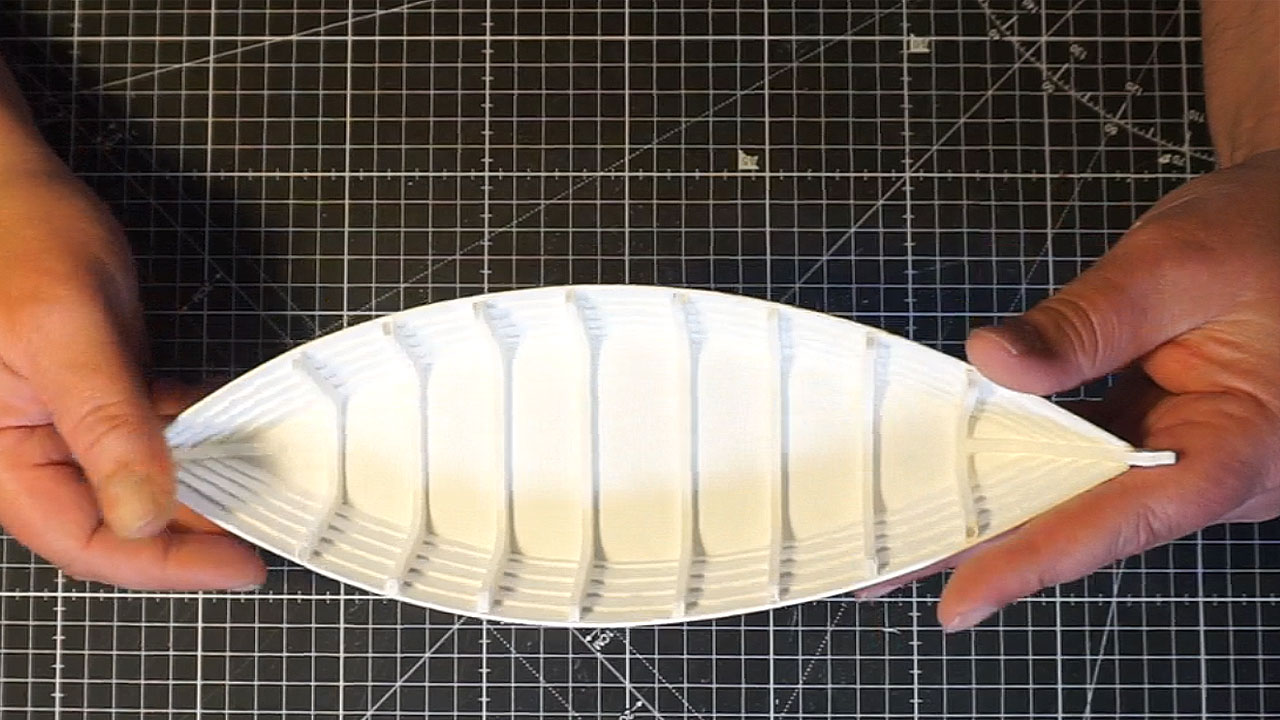

– Gluing in the seat support woods

– Bluring of the brass parts

– Shorten and glue the eye bolts for the mast base

– Installing the bow and stern platforms

– Gluing the seat boards

– Staining the baskets and fittings

– Deburring of fittings such as cleats

– Attaching the rudder pins

– Installing the wooden cleats

– Painting the rudder

– Installing the rudder fittings

– Preparing the mast and spars

Part 1 of this project you can find here and part 2 here.